Kendu: Sustainability Starts With Us

Sustainability is a crucial focus in today’s business landscape. Every single aspect of our business reflects our ethos, which requires meticulous attention to detail. A company that cares about sustainability is a company that cares about its customers.

At Kendu, we have long been giving sustainability the attention it deserves, aligning our manufacturing practices to minimise environmental impact. Today, we are eager to share some of the cornerstones that define our journey toward becoming a sustainable business.

1. Choice of suppliers

Ensuring the sustainability of your business begins with selecting partners and suppliers who share your commitment to sustainable development.

At Kendu, we hold our suppliers to rigorous standards, requiring FSC certification for our cardboard packaging and PEFC certification for our wooden packaging. In transportation, we prioritise the use of low-density polystyrene corner pieces—100% recyclable and composed of at least 30% recycled material.

Our suppliers are your suppliers. And our demand is your demand.

2. Circular manufacturing

Why let a product go to waste when it can have a second life?

At Kendu we work with 100% recycled textiles from plastic bottles (PET) that we print using a more sustainable process for more eco-friendly campaigns. Moreover, our frames and light boxes are crafted from 100% recycled and recyclable aluminium profiles, further enhancing our commitment to circularity.

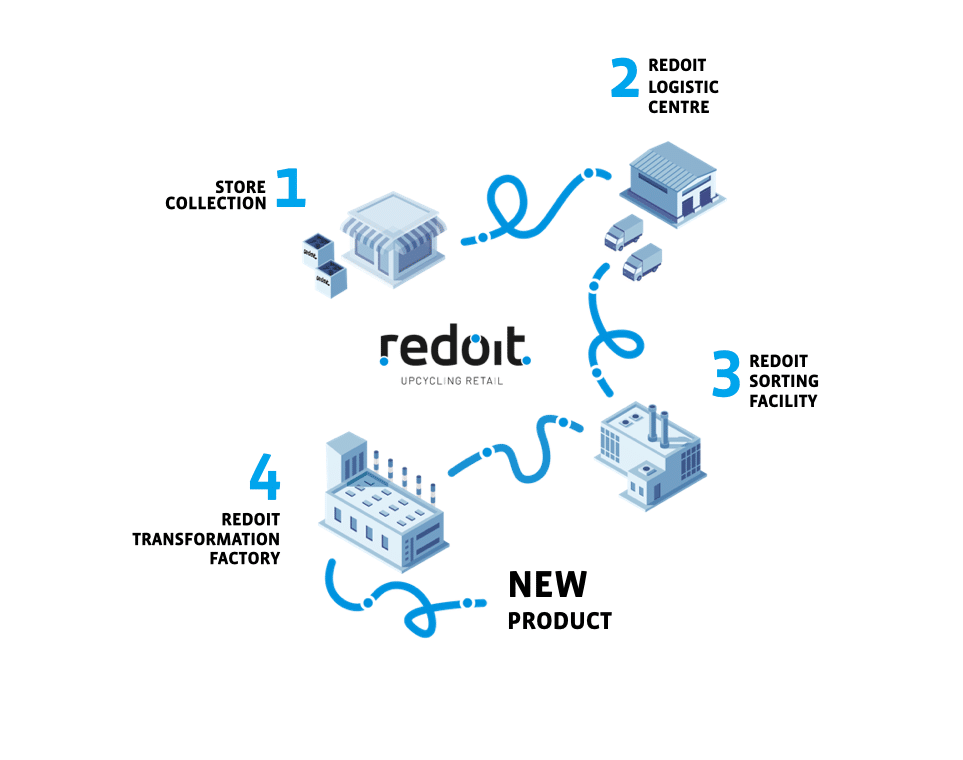

Did you know that Kendu offers textile collection and recycling services? With Redoit, textiles from each campaign can be repurposed into ked.eco—an environmentally conscious alternative to silicone for adhering textiles to frames.

3. Ked.eco, sustainable Keder

Without a clear focus on sustainable development, Kendu’s business model could pose challenges for sustainability. The aluminium frame or the light box are reusable, but what do we do with all the textiles from previous campaigns that are no longer useful? How much waste does each campaign generate?

Kendu has developed a process that transforms collected textiles into a sustainable alternative to silicone textile. Made entirely from recycled polyester, ked.eco eliminates the need for separate recycling.

But are recycled textiles truly sustainable?

4. Sustainable dye sublimation printing

Today, Kendu’s textile printing process relies on sublimation. This method is known for its environmental friendliness, as it minimises CO2 emissions, waste, and pollution, further aligning Kendu with the 17 sustainability goals outlined by the United Nations.

Furthermore, the ink used in our printing operations is water-based and free of volatile organic compounds, meeting stringent European REACH and US TSCA regulations for chemical product safety.

It’s a win-win-win: better for you, better for us, and better for our planet.

5. Packaging: The visible face of our product

Packaging is an integral part of a brand’s identity, which means that any changes to it can have a drastic impact. A bad decision about the packaging can affect how customers perceive our company, and in today’s environmentally conscious world, using excessive plastic and non-recyclable materials can tarnish a brand’s image.

At Kendu, we’ve made a conscious choice to use Kraft paper for our packaging, a sustainable and eco-friendly alternative. All our packaging suppliers are certified by sustainability organizations such as FSC or PEFC. Moreover, our packaging for Flowbox is EcoDesign certified, boasting eco-friendly design principles and 100% recyclability, which also reduces transport costs.

Kendu offers a range of environmentally friendly products, exemplified by Flowbox—a solution designed to minimise environmental impact and carbon footprint. Beyond environmental benefits, Flowbox also contributes to energy conservation through reduced consumption.